A know-how, the result of more than 50 years of experience

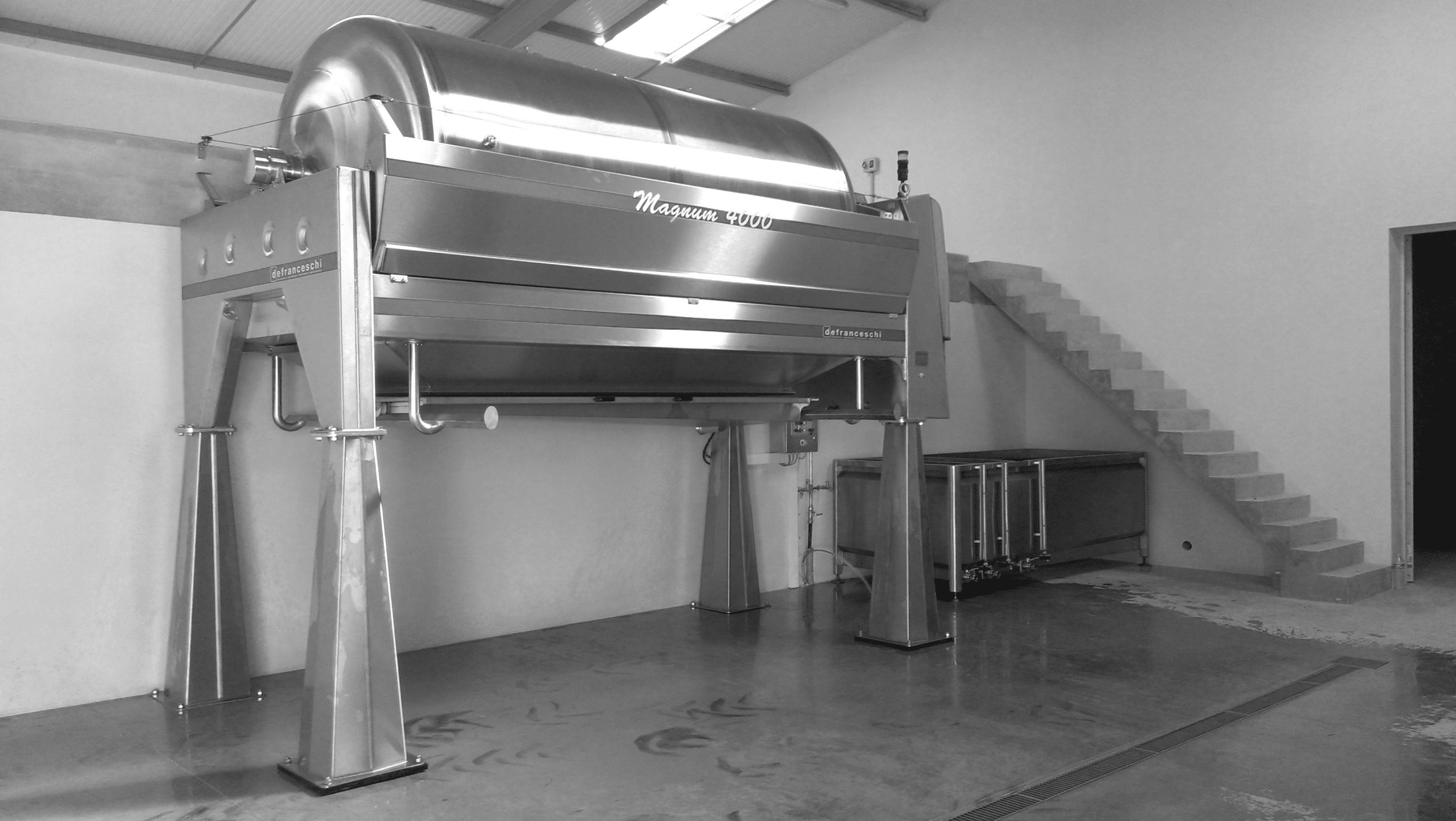

Since the invention of this machine in the 1970’s, we have been the leader in the field of riddling of sparkling wines. With 50 years’ expertise behind us, and always in the forefront of innovation, Oeno Concept manufactures in France its range of riddling machines Gyropalette® with our TSR® and riddling boxes.

Find out more