PRESSING DEPARTMENT

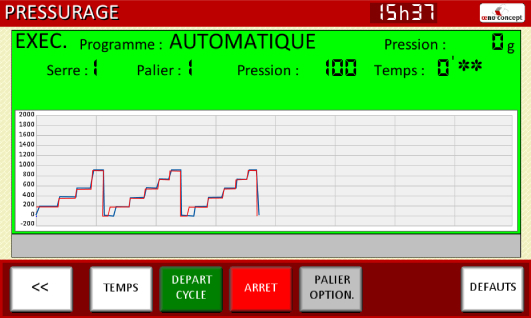

Designed to meet the highest quality standards, our champagne press performs pressing in gradual pressure steps. On the console screen, you can follow the pressing curve in real time.

In our standard programs, the pressures applied to the cuvée are rather gentle, to extract the purest juice. For the taille and rebêche, on the other hand, the stages are shorter and the pressure higher.

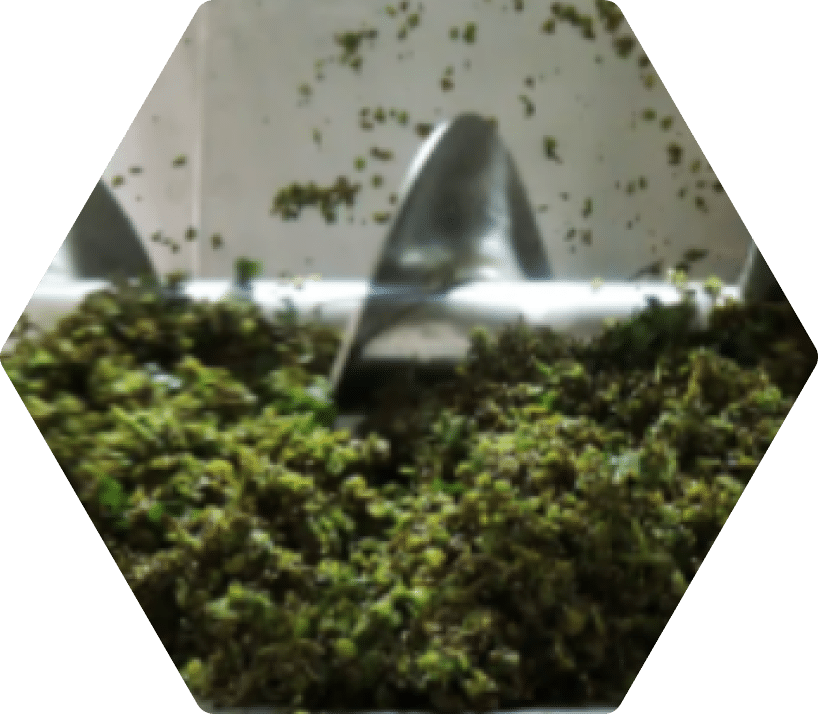

There are one to four retrousses between the clamps to stir the grapes.

Complete pressing time with our supplied programs is around 3 hours.

CIVC QUALITY-APPROVED PRESS

To comply with the quality requirements of the Comité Interprofessionnel du Vin de Champagne, our Magnum® range of Champagne presses is approved for quality.

EASY CLEANING

The cage has a satin-finish exterior and a high-gloss annealed interior, making it easy to clean between presses. The stainless steel press itself is easy to clean during the harvest. At the end of the harvest, restore the shine to the frame and cage, and remove traces of tannin with special stainless steel cleaning products.

We also supply cleaning products for the press and its accessories.